Understanding the SI Unit of Pressure in Engineering and Repair Services

In the fields of engineering and technical repairs, understanding the SI unit of pressure is crucial. This article delves deeply into the concept of pressure, its measurements, and its significance across various disciplines, particularly in the domains of auto repair, farm equipment repair, and structural engineering.

What is Pressure?

Pressure can be described as the force exerted per unit area on the surface of an object. In practical terms, pressure plays a critical role in a myriad of applications, from lifting vehicles to maintaining the structural integrity of buildings.

The SI Unit of Pressure: Pascal

The SI unit of pressure is the pascal (Pa). Named after the French mathematician and physicist Blaise Pascal, one pascal is defined as one newton per square meter (N/m²). This unit is part of the International System of Units (SI) and is widely used in engineering contexts.

Understanding the Pascal in Engineering Contexts

To appreciate how pressure is applied in engineering, we can look at its use in several sectors:

- Auto Repair: Pressure measurement is essential in various automotive systems, including tire pressure, hydraulic brakes, and fluid dynamics within engines.

- Farm Equipment Repair: Proper pressure levels in machinery ensure optimal performance and longevity, particularly in hydraulic systems found in tractors and harvesters.

- Structural Engineering: Engineers must calculate pressures on structural components to ensure that buildings can withstand various loads such as wind, snow, and occupancy.

How to Measure Pressure

There are several ways to measure pressure, and these methods often involve different units, but they can all be converted to pascals:

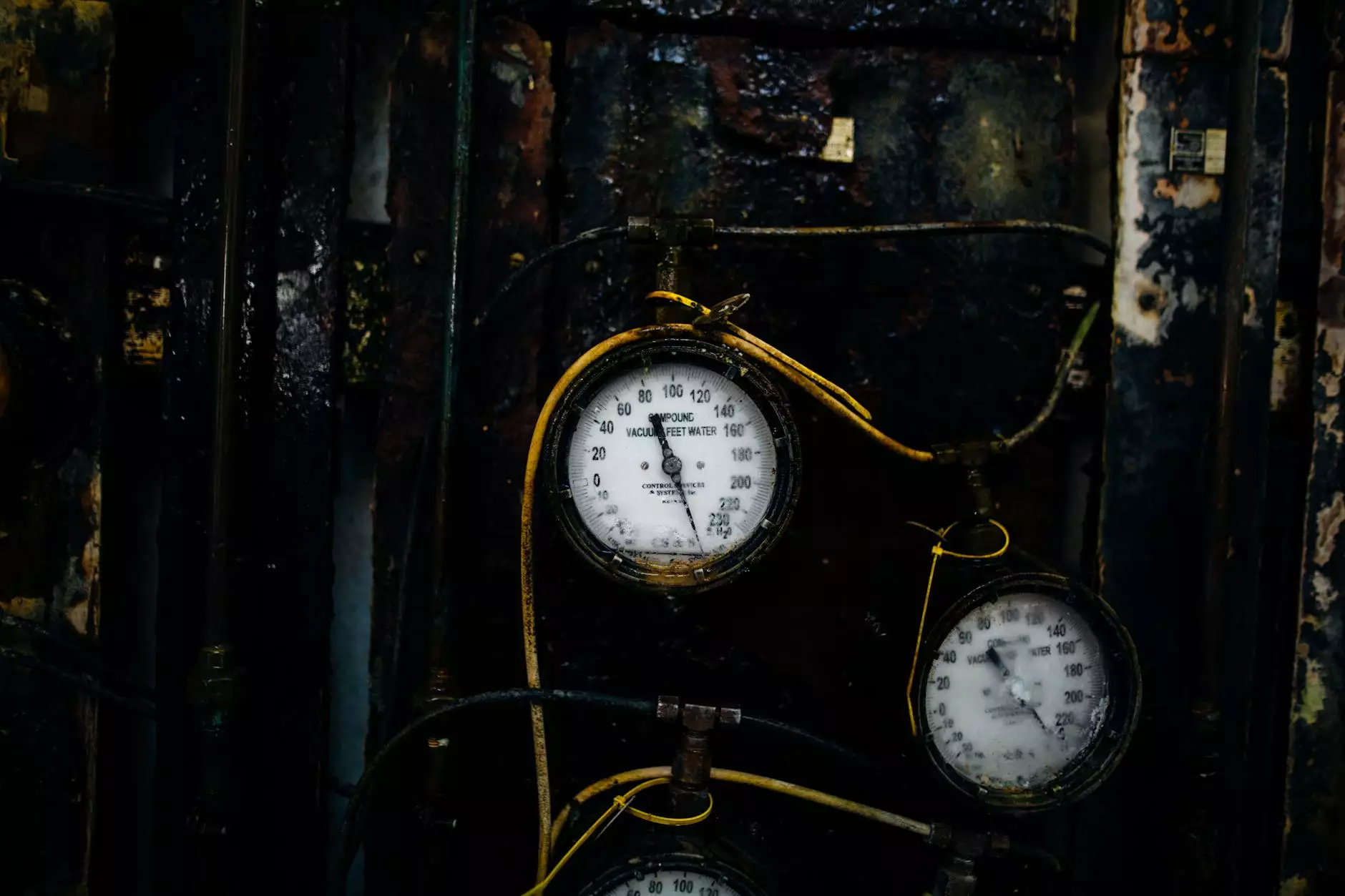

Important Pressure Measurement Instruments

Some commonly used instruments for measuring pressure include:

- Manometers: These devices utilize columns of liquid to measure pressure differences and are useful in laboratory settings.

- Barometers: Specifically used for measuring atmospheric pressure, essential in meteorology and aviation.

- Pressure Gauges: Often found in automotive applications, these gauges can indicate tire pressure and fluid pressures in engines.

Conversion of Pressure Units

While the pascal is the standard SI unit, pressure can also be expressed in various other units, including:

- Atmospheres (atm)

- Pounds per square inch (psi)

- Millimeters of mercury (mmHg)

To convert between these units and the pascal, one must use specific conversion factors. For instance:

- 1 atm = 101,325 Pa

- 1 psi ≈ 6,894.76 Pa

- 1 mmHg ≈ 133.322 Pa

Applications of Pressure in Various Engineering Fields

Understanding the SI unit of pressure allows professionals in engineering to apply this knowledge practically. Here, we explore how pressure influences different sectors:

1. Auto Repair

In the automotive industry, pressure is a vital factor. Proper tire pressure is essential for safety and fuel efficiency. Low tire pressures can lead to increased tire wear and potential blowouts, while excessive pressure can cause discomfort and reduced grip.

Additionally, pressure monitoring systems (TPMS) are now standard in vehicles, providing real-time pressure readings for each tire, which plays an essential role in vehicle safety. Auto mechanics must understand the implications of pressure in hydraulic systems used in brake systems, ensuring vehicles operate efficiently and safely.

2. Farm Equipment Repair

Farm machinery, such as tractors and combines, heavily relies on hydraulic systems, making pressure an important factor in maintenance and repair. Hydraulic pressure must be adequately monitored and adjusted to ensure these machines perform optimally. Faulty pressure gauges can lead to catastrophic equipment failures, affecting farm operations and productivity.

Farmers utilize equipment that operates under high pressures for tasks such as planting, seeding, and harvesting. Understanding and maintaining the correct pressure levels in these machines ensures that operations run smoothly and efficiently, directly influencing agricultural productivity.

3. Structural Engineering

The role of pressure in structural engineering cannot be overstated. Engineers must calculate the pressures exerted on materials to ensure safety and durability. This involves understanding not just the weight a structure must support, but also external pressures such as wind and seismic forces.

For instance, when designing a building, engineers calculate the wind pressure acting on the structure's surface to determine the necessary strength of materials used in construction. This meticulous calculation ensures that a building can withstand environmental forces without failing.

Challenges and Considerations in Pressure Measurement

While measuring pressure appears straightforward, several challenges can arise:

- Temperature Variations: Pressure readings can be affected by temperature changes, requiring compensation for accurate results.

- Calibration of Instruments: Regular maintenance and calibration of pressure measuring instruments are crucial for reliable performance.

- Environmental Factors: External factors such as humidity and altitude can influence pressure measurements, particularly in sensitive applications.

The Future of Pressure Measurement in Engineering

As technology evolves, so too do the methods and accuracy of measuring pressure. Digital gauges and remote monitoring systems are becoming increasingly common in industries. These innovations allow for real-time data collection and analysis, facilitating better decision-making in maintenance and repairs.

Moreover, the integration of IoT (Internet of Things) technology enables engineers to receive alerts for pressure anomalies, improving preventative maintenance strategies significantly. This advancement helps avoid costly repairs and enhances the lifespan of machinery and structures.

Conclusion

In summary, the SI unit of pressure, the pascal, holds immense significance across various engineering sectors, including auto repair, farm equipment repair, and structural engineering. Understanding pressure allows engineers and technicians to make informed decisions that enhance safety, efficiency, and productivity.

As we move forward, the principles surrounding pressure will continue to be an indispensable aspect of engineering, fostering innovation and driving improvements in machinery and structural integrity. For those involved in these industries, a profound understanding of pressure, its measurement, and its applications is fundamental to success.

For more information on how the principles of pressure apply to our comprehensive engineering services, visit Michael Smith Engineers.